David Luther | Digital Content Strategist | July 13, 2023

More businesses are focusing on supply chain resilience after recent global disruption, with many putting pandemic-driven upgrades in place to mitigate future risks. However, current levels of supply chain stress and disruption remain far higher than they were before the pandemic. The combination of residual pandemic-related issues and new triggers now includes labor shortages, transportation bottlenecks, cyberattacks, extreme weather events and inflation. All of these pressures and more are compounded by unpredictable market demand. So, the question is: What fresh disruption will tomorrow bring, and how should your business handle the challenge?

What Is a Supply Chain Disruption?

A supply chain includes the network of people and companies that create a product and deliver it to a customer. A supply chain disruption is any circumstance that interferes with a company’s flow of production, sales and distribution. Disruptions are the bane of supply chain management and can cause significant harm to a business by slowing shipments, degrading product quality, increasing costs and damaging brand reputation.

At the height of the pandemic, supply chains captured the media spotlight when they broke down, leaving grocery shelves empty as many products, from toilet paper to meat, were hard for consumers to come by. Delivery schedules were fraught with delays, stretching far beyond customers’ level of tolerance. As some of the shipping problems, ransomware attacks and other supply chain issues that plagued businesses between 2020 and 2022 have abated — although they have not completely disappeared — other challenges have arisen, such as oil price spikes and computer chip shortages. Supply chain–risk monitoring company Resilinc estimates that supply chain disruptions increased nearly 50% in the first half of 2022, compared with the same period in 2021.

Supply chain problems can have a severe impact on businesses, often damaging their overall performance. To reduce risks and mitigate the impact of disruptions, companies may employ a variety of supply chain strategies, including preparing backup-supplier arrangements, geographically restructuring supply lines and increasing inventory levels. Digital technologies support these strategies by enhancing supplier networking, visibility and analytical capabilities, allowing businesses to closely monitor their supply chains, detect potential problems and make contingency plans to avoid costly headaches.

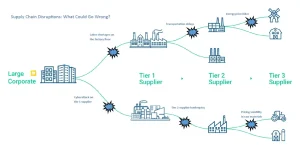

Every handoff along the supply chain is at risk of disruption.

Internal vs. External Risks

Some supply chain risks are initiated within a company, and others come from outside influences that disrupt operations either directly (via a company’s tier 1 suppliers) or indirectly (due to a supplier’s suppliers at tier 2 or beyond). The current semiconductor shortage presents a prime example of a breakdown in a multitiered supply chain: An automaker can’t make enough cars when its (tier 1) supplier of engine management systems is delayed because a (tier 2) maker of fuel injection modules can’t get enough chips from its (tier 3) semiconductor supplier. A midsize company may have anywhere from a handful of suppliers to dozens of them at different levels of its supply chain and, therefore, may be susceptible to both internal and external risks.

- Internal risks. Internal issues may arise in the C-suite when a new business strategy or reorganization fails to consider supply chain implications. More often, the roots of disruption can be traced to a procurement office or other supply chain management function, which may suffer from poor inventory management, neglected supplier relationship management, lack of contingency planning or insufficient visibility across the supply chain.

- External risks. The list of external risks is long: hurricanes, ransomware attacks, blockages at ocean ports, geopolitical conflicts, demand fluctuations and more. Events like these can be more challenging than internal disruptions, since they often fall outside a company’s control, such as a political crisis in a different country that supplies products to a business. The tiered nature of supply chains also increases a company’s exposure, particularly when the supply chain crosses international borders. It takes a concerted effort to keep on top of suppliers feeding into your operations at tier 1, tier 2, tier 3 and beyond. And there’s only a 50-50 chance that any of these suppliers have measures in place to mitigate their own disruptions, according to the Business Continuity Institute (BCI), which helps explain why about one in 10 companies experienced more than 10 disruptions in 2022.

Key Takeaways

- Supply chain disruptions have been accelerating in recent years, creating ongoing challenges for supply chain managers.

- The causes of disruption vary widely, from labor shortages to extreme weather, and many issues are increasing in intensity.

- Supply chain disruptions can hurt businesses in a variety of ways from the top line to the bottom line — for example, by slowing shipments, degrading product quality, increasing costs and damaging brand reputation.

- Lessons learned, improvements made and digital controls implemented during the global pandemic are now being applied across newly emerging disruptive events.

The Impact of Supply Chain Disruptions

Many C-suites and boards of directors consider supply chain disruptions a major risk to business. One consequence is an inability to manufacture at full capacity. In fact, 23% of companies surveyed by the Federal Reserve indicated that their supply chains represented a significant manufacturing constraint in the fourth quarter of 2022.

Another way to understand the impact of supply chain disruptions is to look at what happens in a worst-case scenario. When a giant cargo ship blocked the Suez Canal in March 2021, it shut down a trade route that typically carried $9.6 billion worth of shipments every day. Delayed and rerouted cargo included everything from wine to car parts, affecting a wide array of industries from the restaurant business to auto repair shops. Once unblocked, the ship and its thousands of tons of merchandise were then impounded for three months due to legal issues, which experts say caused global supply chain repercussions for companies more than a year later.

Supply chain disruptions have wide-ranging impacts, from increased costs and canceled orders to reduced business profitability and diminished company valuation. For example, the share price of a major auto manufacturer plunged after it warned that chip shortages would force the business to miss production targets. Here’s a look at some specific disruptions and their effect on various markets.

Types of Supply Chain Disruptions

Stress on the global supply chain remains high, according to the Association of Supply Chain Management’s (ASCM’s) Supply Chain Stability Index. Here are six reasons the market continues to experience disturbances: the COVID-19 pandemic, natural disasters and extreme weather, labor shortages, transportation delays, price volatility and cyberattacks.

Global Pandemics

Global pandemics, such as the COVID-19 pandemic, can disrupt the entire supply chain due to everything from shortages of raw materials to changes in consumer behavior.

The memories of severe COVID-related shortages remain fresh as businesses work to prevent supply chain disruptions: “Companies saw what was happening and tried to front-load their orders to get ahead of delays,” said Matt Mendez, supply chain manager, Physicians Choice, a dietary supplements brand. “Increased demand, paired with a decrease in supply from the virus, resulted in massive lead times and stockouts for certain raw materials.”

Some of the pandemic’s negative effects on supply chains, such as creating transportation bottlenecks, have been receding — but not entirely. Many companies that survived this complex turn of events have shifted from prioritizing lean, “just-in-time” operations to adopting more agile approaches to attain greater supply chain resilience.

Some companies have “reshored” offshore sourcing arrangements, bringing suppliers closer to their home bases. To increase agility, many companies are leaning more heavily on digital controls, for example, and are beefing up inventory to better withstand shortfalls. However, experts warn against complacency, saying that company officials need to remember lessons learned during the pandemic if they hope to face the growing severity of challenges.

Natural Disasters and Extreme Weather

Over 40% of companies include natural disasters and adverse weather events among their top five supply chain risks for the coming five years, according to BCI. Extreme weather events, such as heat waves and large storms, are likely to grow more frequent and intense, according to the U.S. Environmental Protection Agency. And too many supply chain managers have already experienced factory floors flooded by hurricanes, ocean ports closed by freak winter storms, highways blocked by wildfires or food supplies decimated by drought.

Companies that take precautions stand in better stead. A Harvard Business Review case study, for example, describes how a major coffee producer used satellite imagery to locate its New Orleans production facilities well above sea level, enabling it to restore operations more quickly than other businesses after Hurricane Katrina in 2005. Advance planning and preventive measures like these need to be supplemented by early-detection systems. Some companies use artificial intelligence (AI) to scan climate news and predict events, while others purchase feeds from risk analytics services. For many supply chain managers, weather data provides the impetus for creating detailed contingency plans.

Labor Shortages

Both the BCI report and ASCM’s Supply Chain Stability Index list labor shortages as a top issue that is hindering supply chains today. Truckers are in short supply, leading to transportation delays. Unfilled jobs on factory floors have contributed to rising accident rates. Within the supply chain function itself, Gartner has reported that only 27% of chief supply chain officers (CSCOs) believe they have the employee talent needed to keep supply chains performing well.

Automating supply chain processes can help by freeing the current workforce from preoccupation with many tedious manual tasks related to monitoring the supply chain and giving them time to take on more complex and satisfying work that allows businesses to retain employees.

Transportation Delays

While labor issues rank as the No. 2 stress in the Supply Chain Stability Index, transportation and logistics problems are No. 1. Labor and transportation issues are related, of course. Plus, driver shortages are compounded by higher energy prices for shipping products and more delays due to weather or customs holdups at border crossings.

“Effective inventory management has never played a more critical role,” according to the index’s authors. Ensuring uninterrupted deliveries requires inventory management that is integrated across sales, operations, procurement and other relevant departments, they advise.

Price Volatility

As interest rates have continued to rise, inflation is a question mark hovering over everything from customer demand and labor costs to purchasing power and inventory financing. Energy shortages and their related price spikes are also listed as one of the top five supply chain issues in the BCI report.

To keep close tabs on costs, experts suggest leaning more heavily on digital technologies that will increase visibility, accelerate planning exercises and provide predictive analytics to prepare for impending price hikes.

Cyber Attacks

Supply chains have increasingly become exposed to more and more sophisticated cyberattacks. Supply chain breaches increased dramatically in 2022, as cyberattacks accelerated as well. Cyberattackers often break into smaller companies in a supply chain in an effort to ultimately reach a big buyer as their main target.

In the BCI report, cyberattacks and data breaches were ranked as the top threat to supply chains in the coming months, as well as over the next five years. In addition to protecting employees, customers, platforms and data from cyberattacks by boosting cybersecurity tactics, companies need to collaborate more with supply chain partners and implement third-party risk management procedures to ward off attacks.

How to Handle Supply Chain Disruptions

Experts today acknowledge the rough terrain that supply chain managers find themselves traversing. For example, ASCM refers to “the Great Supply Chain Disruption” in its outlook for 2023, while Accenture notes that the supply chain is undergoing “a perpetual storm of disruption,” and Gartner calls disruptions both “omnipresent” and “unpredictable.”

Having a plan to handle disruptions is essential. KPMG management consultancy advises that “when disruption is constant, an organization’s preparation for key supply chain trends can be a significant competitive advantage.” So, what are best practices for establishing and running resilient supply chains that can overcome disruptions?

- Identify potential risk factors.

Supply chain managers need to create a structure for tackling supply chain disruptions, and they can start getting organized by cataloging and addressing known risks. Classic supply chain risks, such as supplier bankruptcies, can be more easily measured and managed than less familiar sources of disruption. To assess exposure, a supplier’s financial history can be combined with knowledge of the product lines in a company that rely on that supplier’s solvency. Certain unknown risks, on the other hand, can be moving targets. Today, for example, unpredictably rising interest rates can have an insidious impact on the cash a company has tied up in inventory. At the same time, companies can help lift the curtain on the unknowns by taking advantage of a variety of tactics, such as employing predictive analytics, what-if scenarios and estimations of value-at-risk.

Identifying risks in advance is one thing, but supply chain managers also need to put digital systems in place to detect disruptions that are unfolding in real time.

- Develop a contingency plan.

A world of risks requires agile supply chain operations that are based on alternative supplier relationships and other short- and long-term strategies to avert problems and remediate any that do occur. A basic contingency plan would map out a series of steps, from identifying the cause of a disruption to prioritizing critical operations, rebalancing inventory, shifting orders to alternative vendors and communicating plans to stakeholders. A key proviso is that contingency plans need to be routinely reviewed and updated, or they may not be useful enough when they’re needed most.

- Monitor and analyze your supply chain data.

Visibility clears the path to uninterrupted supply chain operations. Company executives surveyed by PwC cited cloud computing and the Internet of Things (IoT) as the top two technologies improving visibility today.

To gain visibility, companies use digital tools, such as scanners, to derive tracking and maintenance data from myriad IoT devices on trucks, in warehouses and on the factory floor — then enable analysis of that data via cloud-based networks. Layering on software, such as demand planning and inventory management applications, helps to complete this picture for Beekman 1802, a skin care company. “We know when we’re going to be out of stock, and we have mechanisms to reach out to suppliers and expedite things,” said COO Tomei Thomas.

- Implement automation solutions to help manage disruptions.

With the ability to monitor every stage of the supply chain process, companies can increase efficiency and avoid unnecessary costs. In a warehouse, for example, sensors can track inventory levels and automatically reorder supplies when they reach a set threshold to avoid stockouts. While in transit, sensors can report the location and condition of goods, allowing companies to reroute orders, if problems arise, to avoid delays.

In the back office, robotic process automation can help prevent ordering mistakes by reducing the errors associated with manual data entry. Many companies have begun to deploy AI to enhance the predictive capabilities of automated functions, like reordering and rerouting products. Amid labor shortages, some companies are using robots that can pick products off shelves and pack shipments in the warehouse. Delivery drones are also being tested in some cities.

Over three-quarters of economists see businesses optimizing their supply chains in these and other ways, according to a World Economic Forum outlook for 2023.

- Strengthen supplier relationships.

Suppliers shouldn’t be viewed only as potential sources of risk but should also be treated as allies in avoiding disruptions. “Make sure you’re developing those relationships constantly,” said Tiffany Krumins, founder of Ava the Elephant, a maker of interactive medication dispensers for children that is now part of Better Family.

A recent Gartner survey showed 77% of chief supply chain officers were working to improve collaborative relationships with key customers and suppliers. For example, some companies are developing shared inventory-hedging strategies to secure supplies, decrease lead time and reduce risk. Others have found strength in building relationships with a diverse group of suppliers, such as minority- and women-owned businesses, that are introducing new approaches to agility and resiliency against disruptions.

While many companies are making strides toward managing supply chain disruptions, more work remains to be done. For instance, only about half of companies actually check and validate their suppliers’ business continuity plans, according to BCI. And only about a third of companies in the PwC survey are using digital collaboration tools with suppliers, putting them on the road to the ultimate digital supply chain ecosystem that is envisioned as a best practice.

Manage Your Supply Chain Regardless of Disruptions With NetSuite

NetSuite’s supply chain management software aims to keep operations running smoothly, ensuring that all workers and materials are available at the right time and place. NetSuite procurement capabilities drive accuracy throughout the purchasing process while supporting collaboration with suppliers. In addition, integrated demand planning, inventory management and predictive analytics optimize supply chain strategies and streamline tasks to ensure that supply plans are executed without disruption and products are delivered as promised.

The bottom line? As Michael Card, vice president of finance for Crumbl Cookies, put it: “We’ve been able to increase profitability by improving visibility into inventory value, days on hand and other critical information with NetSuite.”

Supply chain disruptions have become a permanent fixture of supply chain management. Disruptions can be caused by a range of factors, from labor shortages to extreme weather, and these challenges are only increasing in frequency and intensity. Their impact can be far-reaching and damaging, affecting everything from shipping time to product quality, cost and brand reputation. The global pandemic has provided businesses with important lessons about the need for agile operations, catalyzing improvements in strategies, tactics and digital controls. As companies apply these mechanisms to prepare for and mitigate the impact of new and different disruptive events, businesses are building the resilience they need to remain competitive in today’s volatile marketplace.